Modluar Inking Rollers

Ink Transportation for Numbering

With the modular inking rollers by Seprinto ink transportation for your numbering press is easier, faster and cost and ink saving.

Introduction

The process and ink for numbering printing come with particular features. The ink for the numbers is shallow and often has specific characteristics such as magnetic and fluorescent particles. The ink quantity adjustment is essential so that these inks can be read correctly later in ATMs and other automats.

Seprinto has extended experience in numbering printing and is always looking for innovation or alternative solutions to increase quality and decrease ink consumption. With our new patented Modular Inking Rollers, we offer a versatile and straightforward to use solution for ink transportation from the numbering ink ducts to the numbering ink fountains.

Rollers

Another novelty is the entirely new type of roller function and system. Seprinto presents the usage of segments instead of entire rollers, which bring many advantages:

- No friction between plastic and rubber rollers

- Better control of ink quantity

- Less or even no flying ink

- A more regular and precise print

- No wear of the rubber in the unused parts

- Less roller coating costs

All rubber rollers should be changed for the best and most efficient effect.

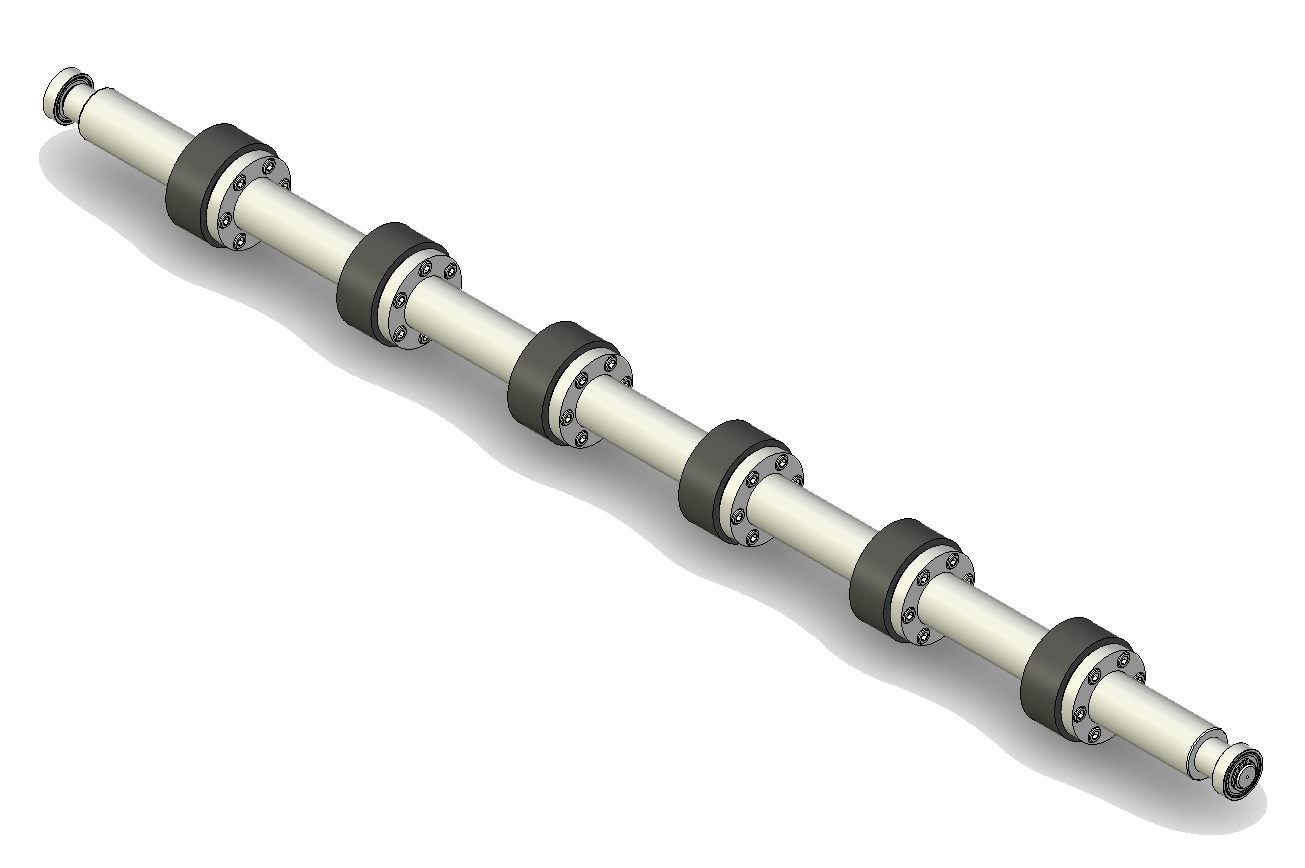

The individual segments are fixed on an eccentric mounting specially developed for the rollers. This construction allows keeping the original concentricity of the rollers.

Simple and precise installation of the segments

This system is adaptable to all types of ink. The base of each roller segment is the same before being coated with different types of rubber.

Segments:

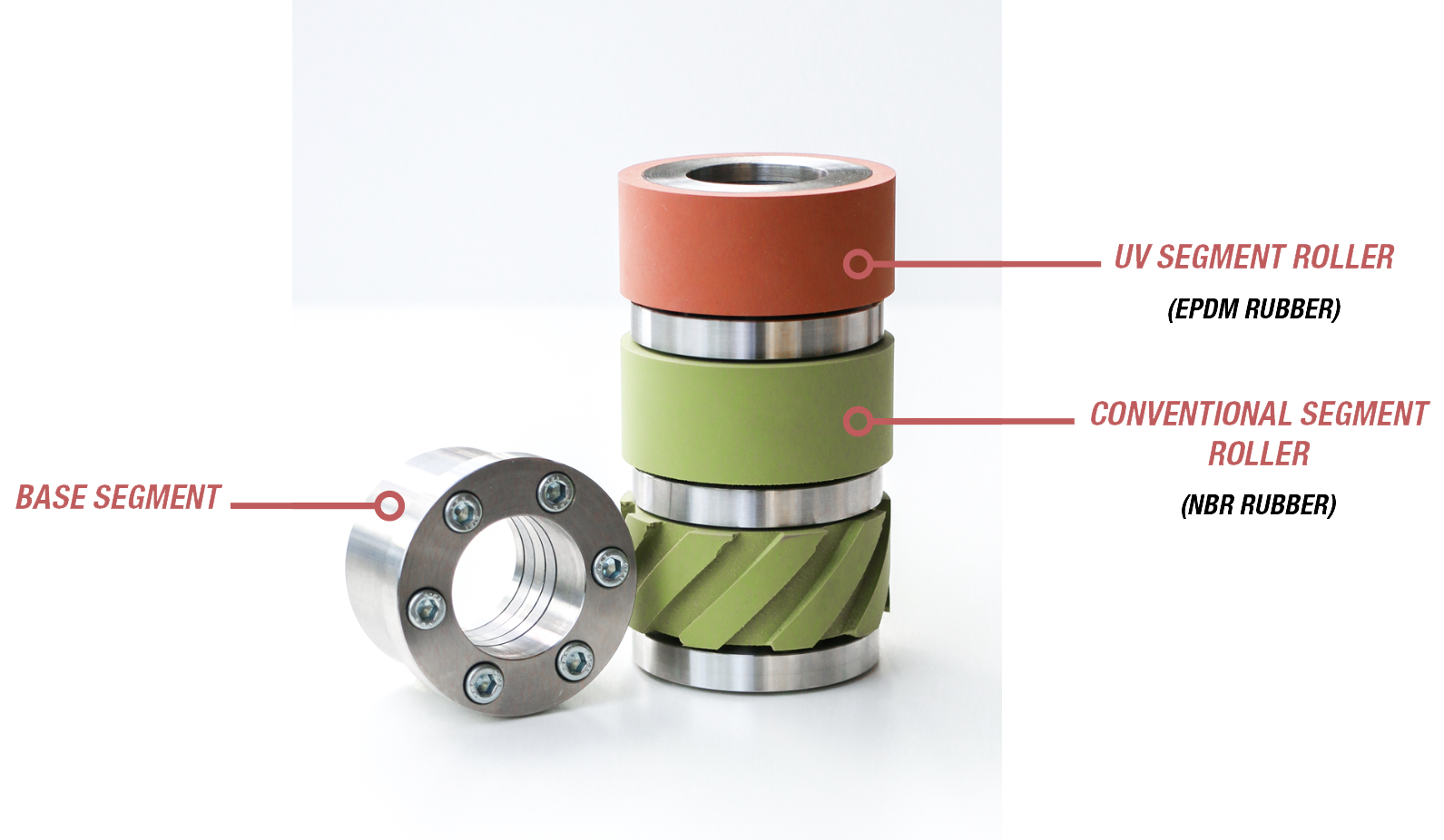

Depending on your ink and your needs, we propose two different types of rubber: NBR rubber (conventional ink, green) and EPDM rubber (UV ink, red).

The recommended hardness stays the same as that of the current rollers, i.e. 40 Shore A.

Segment Concept

Revolutionary attachment of the rollers

The roller segment is easily fixed on the steel shaft. The inner clamping system with two spring-loaded eccentrics allows a firm halt on the shaft while still keeping a perfectly circular outer shell.

IMPORTANT:

The system is designed so that it is possible to remove or add any segment without dismantling the roller bearing!

Vibrator

Vibrator concept

We also offer our Modular Inking Rollers System for vibrators, where the construction slightly differs from our standard Roller Segments due to the size difference of the roller (60 mm).

- The segmented system for the Vibrators offers many advantages:

- Guaranteed accuracy of ink pick-up surfaces

- Reduced number of pre-cut vibrators

- Elimination of risk of bad cuts

- Reduced footprint

- Less roller coating costs

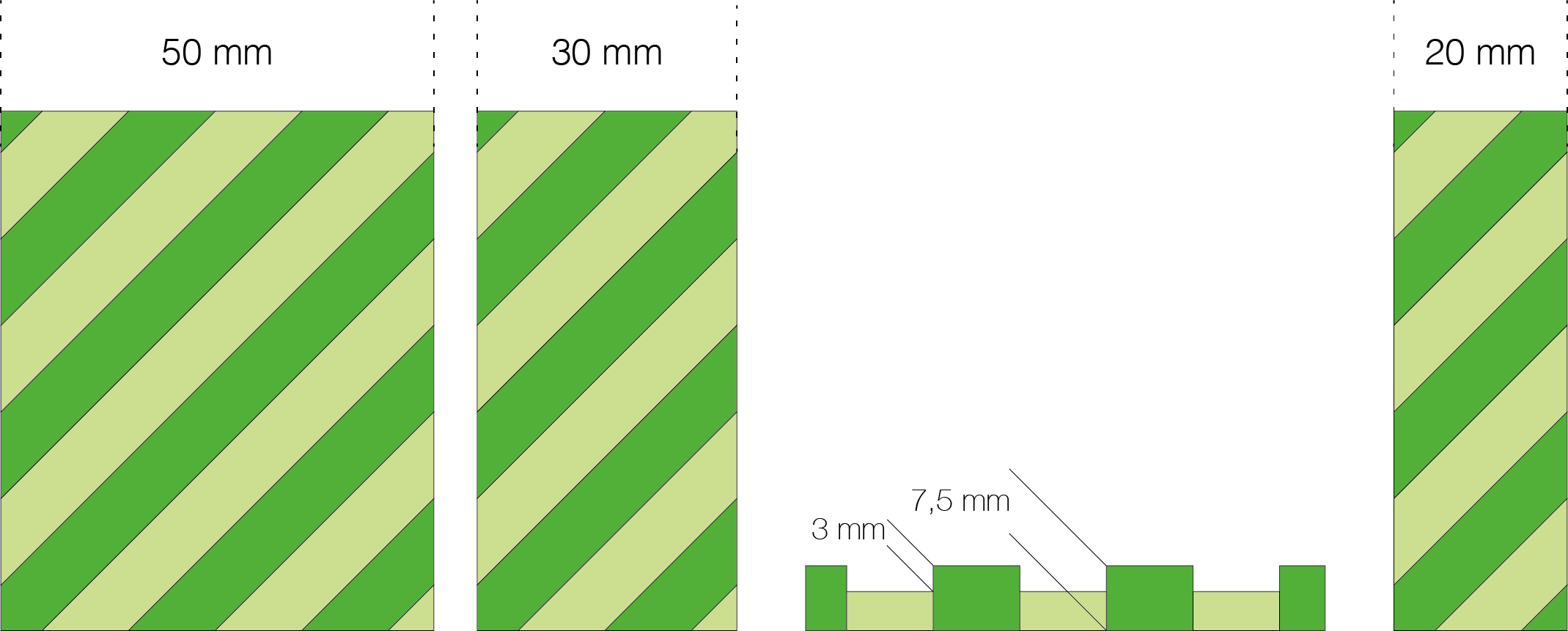

It is possible to order pre-cut vibrators with a reduced ink pick-up. The cut surface increases the ductor’s travel, thus improving the accuracy and smoothness of the ink fountain setting and transfer. The bevelled cut guarantees a constant and even contact between the ductor and the transfer roller. The vibrator can be cut in various percentages of the surface to reduce the ink pick-up by 25%, 50%, and 75%.